| PROJECT AND CONSTRUCTION OF LOCOMOTIVE A2 |

|

| In one of the visits made by the members of the Tren de Palau to The Harz line we saw how a locomotive that looked like a switcher was used for the same services as their steam mates. |

|

|

|

|

The new A2 diesel currently being built at Tren de Palau is a locomotive inspired by DDR’s V110 series. These locomotives were for mixed use, regularly pulling light cargo trains or commuters in branch lines amongst other services. In 1988, 10 units of this series were converted to meter gauge

to provide service to the Harz railway.

Tren de Palau’s locomotive will not be the exactly the same as the original one. We have always been characterized by how we prioritize technical specs and functionality over modelism.

Mechanically the idea is the same as the real locomotive: It will also be diesel-hydraulic, but conceptually different and of a simpler design.

A hydraulic circuit has been designed by our members, which has a certain complexity due to the amount of elements that comprises it, but conceptually it’s simple, adapted to our needs, hopefully with low maintenance requirements, easily fixable and with standardized and economical spare parts. |

|

Steam engines are really beautiful but require a huge effort both in maintenance and operation, so when “Big-Viñas” failed some time ago we considered building another locomotive to supplement it.

If we wanted to do build a steam locomotive, the project would have been too long and that it would not have solved the Trains necessities.

That valiant locomotive we saw at Harz came to mind, so we studied the pros and cons and, as we had just finished our type 900 coaches, we decided to build it

The current necessity of ours is to have a simple and powerful locomotive like Big Viñas. To obtain a high traction effort it was necessary to have an axle load of 500kg with Co-Co bogies, obtaining a coupler force of around 600kg

This locomotive of heavy German character will be in line with the 900 type coaches that run at Tren de Palau |

|

|

|

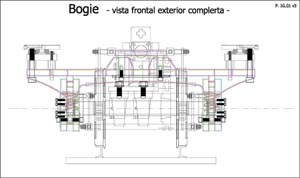

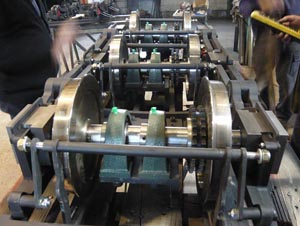

| After defining the general limits (basic dimensions, general aesthetical distribution and weight), design for the conceptual bogies and frame started.

The first structural design where the two bogies, measuring 1549mm long , weighting around 398kg and having 3 hydraulic motors each (one per axle)

Afterwards, the design of the frame, bodywork, hydraulic circuit, desks, electro pneumatics,.. was finished.

In order to design in detail every phase, it was necessary to take into account general concepts of still to be designed phases to avoid interferences, design issues, fitting problems and future equipment (that could not be defined accurately at the moment) and for them to be easily maintained in the future. |

| |

|

|

|

| 10-12-2013 - Assembly blueprints |

|

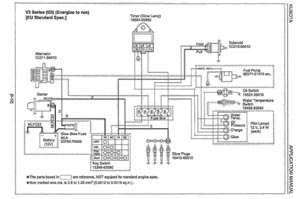

19-05-2014 - Electrical schemes for the motor |

|

| |

|

|

|

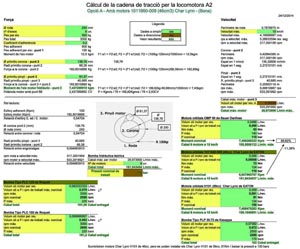

| 25-12-2014 - Calculations for the hydraulic elements |

|

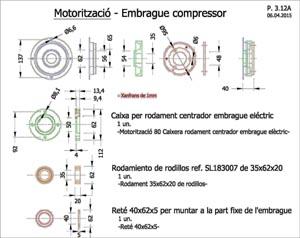

03-05-2015 - Blueprints of the compressor clutch |

|

| |

|

|

|

| 24-02-2014 - We receive the first pieces, the bogie bearing boxes. We already have many elements, like bearings, springs, crowns, etc that together with the motors and brake pistons, we could start build the bogies. |

|

27-02-2014 - The central wheels of these big bogies are flat, just like “Big Viñas”. It eases the entry to curves without affecting the rails |

|

| |

|

|

|

| 10-04-2014 - Finished axles. They will be all for the two Co-Co traction bogies. |

|

20-03-2014 - Once all the laser cut pieces arrived, a first check of the future structure is done. This part consists of 35 different iron pieces cut by laser, some of them repeated up to 32 times, in total being 240 individual parts. |

|

| |

|

|

|

| 27-03-2014 - Jordi, Joan and Sergi checking the pre-assembly of the first bogie |

|

10-04-2014 -

Starting the definitive

phase |

|

| |

|

|

|

| 10-04-2014 - Main bogie assembly starts, with the bearings that will support the motors |

|

14-04-2014 - Jordi Viñas contemplates satisfied the almost finished bogie ready to be disassembled to be painted.

Acabats tindran un pes mig de 398 kg cada un. |

|

| |

|

|

|

| 15-04-2014 - Motors mounted. You can see the parts of the suspension and frame subjection. Is worth to remark that the bogie is of double beam Pennsylvania type |

|

16-05-2014 - Jordi and Ricard adjusting the break tensors in order to mount them provisionally to the chassis to make the first on-track tests. |

|

| |

|

|

|

| 10-04-2014 - Here we have the pair of bogies painted and mounted with all their elements. Each axle has an hydraulic motor, which combined result in a 600kg traction effort on the coupler |

|

22-05-2014 - Purchase of the diesel engine: A 4 cylinder, 63Kw Kubota V-3600-T-E3B 63 kW. The heart of the locomotive. |

|

| |

|

|

|

| 28-04-2014 - The second phase is mounting the frame where all the elements will sit (engine, hydraulic pump, fans, controls and a ton of tubes and valves. |

|

09-05-2014 - We can start seeing how impactful is the structure. Rock deflector mounted. |

|

| |

|

|

|

| 13-06-2014 - The visual impact of the mounted chassis with its bogies with its big 4 cylinder Kubota engine was shocking. We could already imagine it running on the track pulling all of our coaches |

|

On the morning of June 15, 2014, we carried out the first test fun of the chassis, pulled by the L-801 tractor with a “compendium” car for the crew. It was a success. No incidents, it went through the whole line correctly, all the tight curves, crossings, etc |

|

| |

|

|

|

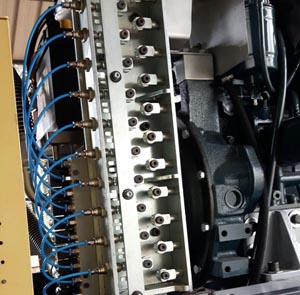

| 17-01-2015 - Here we can show you what will move the driving and braking elements of the new locomotive: A 2 stage 5,4 CV compressor that will be moved by a longitudinal axle that comes from the main engine |

|

30-04-2015 - Mounting multiple pieces that fix the engine to the frame. An power axle moves the fans, compressor and clutch. Hydraulic tubes are built and mounted on the inferior part of the “case” |

|

| |

|

|

|

| 03-06-2015 - View of the power axle |

|

11-07-2015 - More testing at Tren de Palau |

|

| |

|

|

|

| 31-03-2016 - Mounting the main components in the central case |

|

25-05-2016 - Main hydraulic elements mounted |

|

| |

|

|

|

| 09-06-2016 - Cutoff valves to stop the oil flow to the bogies |

|

27-04-2016 -Oil heat exchangers. |

|

| |

|

|

|

| 09-06-2016 - Oil tank |

|

09-06-2016 - Interior of the oil tank |

|

| |

|

|

|

| 07-04-2017 - Painting process of the hydraulic tubes |

|

24-04-2017 - Definitive painting for the frame |

|

| |

|

|

|

| 16-06-2017 - Time to fill up the tanks to check for leaks |

|

01-04-2017 - One of the many details to make transport easier without damaging the future bodywork with pressure from the slings |

|

| |

|

|

|

| 16-06-2017 - Weight of the locomotive in almost running condition, only the bodywork is left |

|

16-06-2017 - Ready to transport it from the workshop to Hostal del Fum’s park |

|

| |

|

|

|

| 16-06-2017 - Unloading the loco using the aforementioned details |

|

16-06-2017 - Ready to mount the pneumatic and electric componentry |

|

| |

|

|

|

| 07-04-2018 - Ricard with Joan checking the pieces that are ready to be mechanized, observed by Antonio |

|

07-04-2018 - Train and loco brake handles |

|

| |

|

|

|

| 08-04-2018 - Piston system that will drive the engine |

|

08-04-2018 - Control valves circuit of the two compressed air circuits |

|

| |

|

|

|

| 08-04-2018 - The tidiness of this engine’s construction if to be admired |

|

08-04-2018 - Control panel almost finished |

|

| |

|

|

|

| 08-04-2018 -One of the details that will make the locomotive a great reproduction of the real one is the heat exchanger for the compressed air and the cab ladder |

|

08-04-2018 - Stairs and handles to climb to the sides |

|

| |

|

|

|

| 08-04-2018 - With the pneumatic system finished we start building the electrical side. On November 2 the electric part was up and running but not the hydraulics as they needed modifications. On January 2019 the electric system is definitively finished |

|

14-03-2020 - All activities are cancelled due to the lockdown imposed by the Spanish government due to Covid 19’s pandemic. The locomotive gets confined in the workshop. |

|

| |

|

| 12-06-2020 - With the hydraulic system fixed, the loco is up and running |

| |

|

| 12-07-2020 - The loco is finished mechanically, multiple tests and adjustments are carried out.All that is left is to build the bodywork |

| |

|

| 06-09-2020 - In September we re-open the railway with the restrictions indicated by the government to control the pandemic. The new locomotive gets to pull passenger trains all naked, causing admiration amongst visitors |

| |

17-10-2020 - The association cancels again all its activities due to new lockdowns.

Even though it was a regional lockdown, it affected a great deal of active members of the railway |

| |

| We restart the activities on April 2021 in a limited fashion, and on May 2nd we reopen to the public. The visitors help keeping work on the loco’s cab with their donations |

| |

|

| 01-08-2021 - The cab being built |

| |

|

| 12-09-2021 - Mounting and fixing the cab to the frame. You can see how big the loco is thanks to Ricard |

| |

| 13-10-2021 |

|

| go up --->> |